Dimensional Stability in Engineering Plastics: A Key Factor for Durability

Dimensional stability is one of the most critical properties of engineering plastics, influencing the quality, durability, and functionality of products. Choosing the right material helps prevent problems such as deformation, expansion, or contraction due to temperature fluctuations, humidity, and mechanical stress. In this article, we explore the importance of dimensional stability in engineering polymers and their advantages over metal materials.

What is Dimensional Stability in Plastics?

Dimensional stability refers to a material’s ability to retain its shape, size, and functional properties throughout its lifecycle. Several factors influence stability, including temperature variations, moisture absorption, and internal stresses.

High-performance plastics with low thermal expansion coefficients, minimal moisture absorption, and reduced internal stress are preferred in demanding industrial environments, ensuring precision and reliability even in extreme conditions.

Problems Caused by Poor Dimensional Stability

If a material lacks sufficient dimensional stability, it can lead to:

- Product deformation – plastic components may expand or shrink, leading to improper fitting.

- Reduced mechanical properties – increased internal stress may cause cracks or material failure.

- Assembly issues – unstable materials complicate processing and installation.

These issues result in product failures, increased manufacturing costs, and potential safety hazards.

Why Choose Dimensionally Stable Plastics Over Metals?

Plastics are increasingly replacing metals due to numerous advantages:

- Lower production costs – engineering plastics are often more cost-effective than metals.

- Lighter weight – plastic components reduce overall weight, improving energy efficiency.

- Corrosion resistance – unlike metals, some plastics are resistant to chemical exposure and corrosion.

- Superior electrical properties – engineered plastics provide enhanced insulation properties.

- Improved friction and adaptability – plastic materials better accommodate dynamic systems.

How to Improve Dimensional Stability in Plastics?

- Reinforcement with glass fibers – enhances resistance to temperature changes and improves mechanical strength.

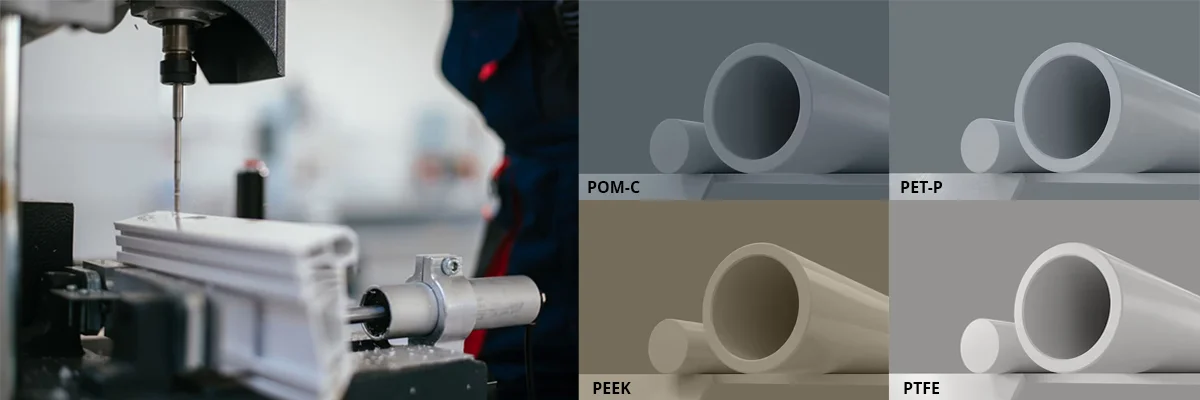

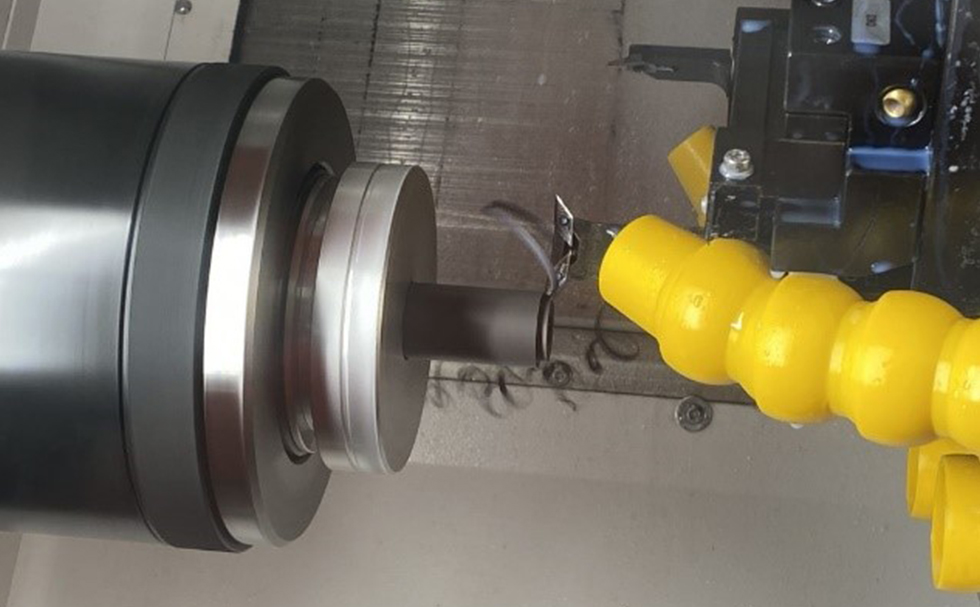

- Proper manufacturing techniques – injection molding, compression molding, and plastic turning impact internal stress and stability.

- Moisture control – reducing water absorption is essential for maintaining precision.

- Thermal expansion management – selecting materials with low thermal expansion coefficients

-

Annealing - the first prerequisite for the stability of technical plastics

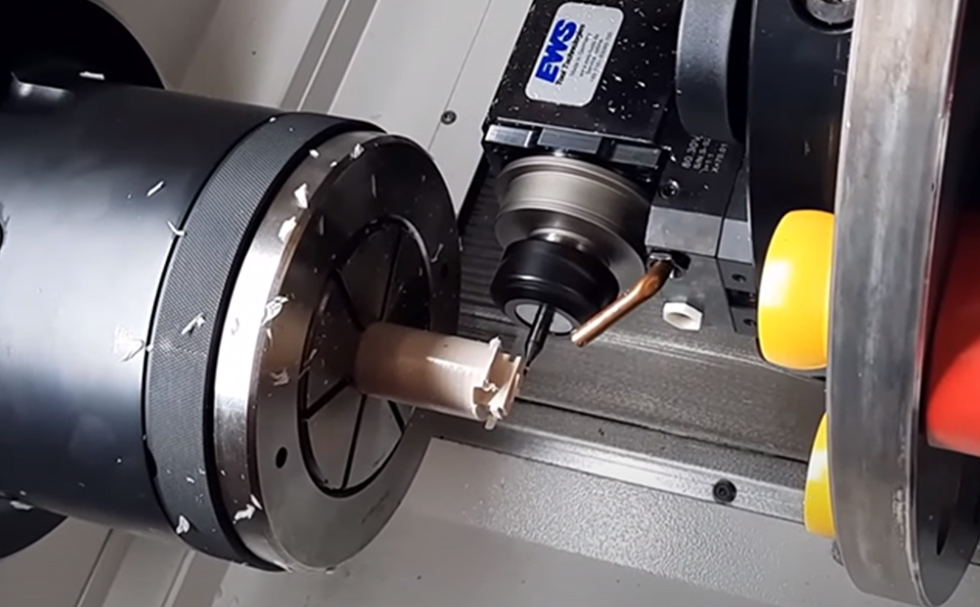

Plastics milling

Plastics milling Injection molding

Injection molding Compression molding

Compression molding Plastic turning (PEEK)

Plastic turning (PEEK)

Industries Where Dimensional Stability is Essential

Dimensional stability is crucial in precision applications, such as:

- Sealing elements – dimensional changes can cause leakage.

- Electrical connectors – precision is key for functionality.

- High-temperature components – resistance to thermal fluctuations prevents deformation.

- Medical and pharmaceutical equipment – where high accuracy and hygiene are mandatory.

Selecting the right engineering plastic and manufacturing process ensures long-term functionality, durability, and quality. With advancements in polymer technology and reinforced thermoplastics, plastics are becoming a superior alternative to metals, offering greater adaptability, lower costs, and enhanced mechanical performance.

Mitsubishi Chemical Advanced Materials (MCAM) offers a comprehensive range of engineering polymers to meet diverse engineering plastics.

Need help choosing materials?

For an optimal material selection solution, please contact our experts who will help you choose the right polymer for your specific product requirements.