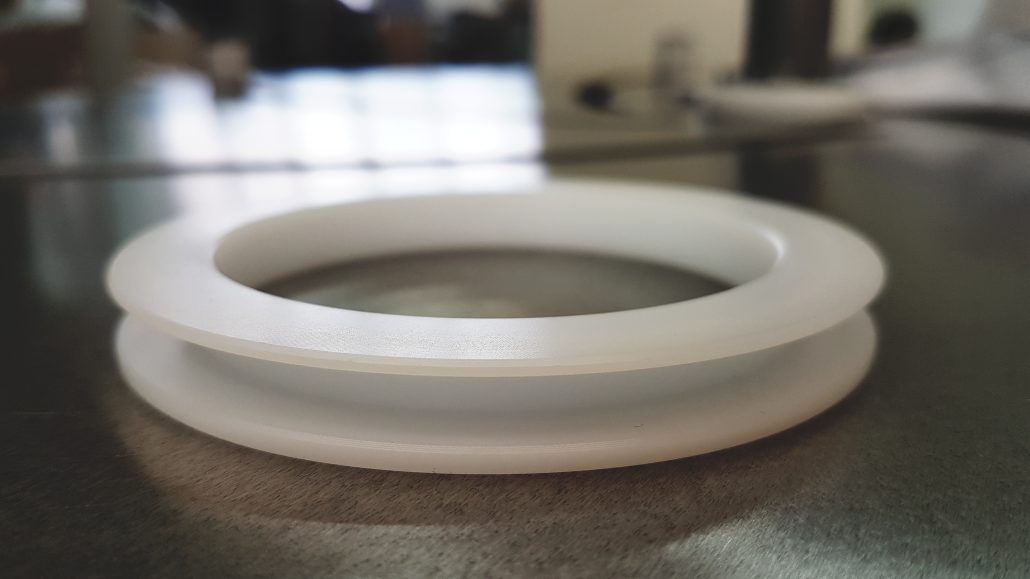

Standard and special custom-turned seals

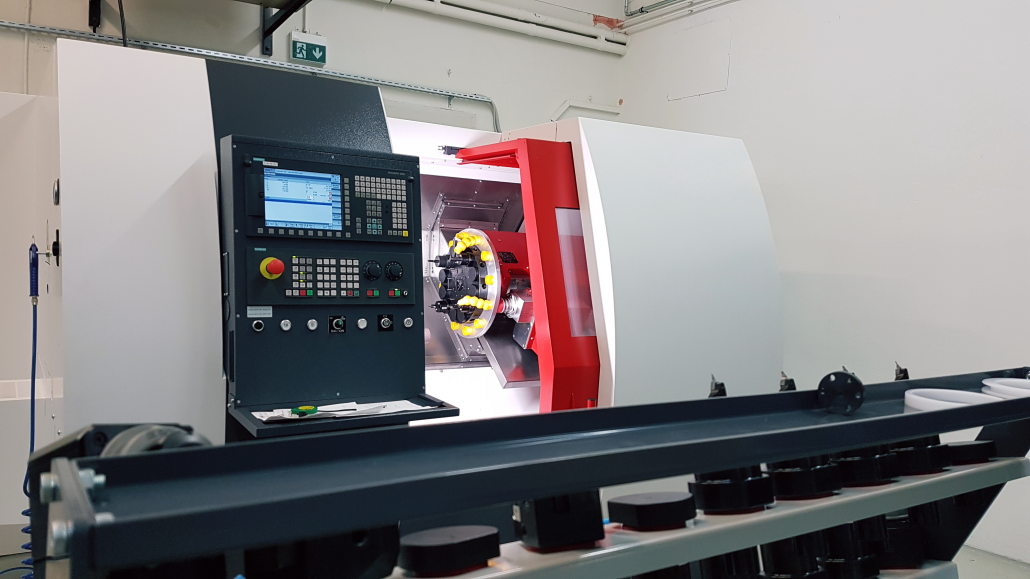

For those who demand reliability and precision in sealing your systems, we offer a solution of high-quality standard and special turned seals. Using a high-tech machine, a 5-axis CNC lathe, we produce dedicated seals tailored to the needs of your application.

With a wide range of raw materials - elastomers and plastomers - we offer solutions for sealing hydraulic and pneumatic cylinders in a variety of applications.

- Seals are produced within 1-2 days!

- We can manufacture up to an outside diameter of 660mm and a height of 610mm!

- Smaller quantities can be ordered.

- We can produce a complete set of used seals!

- Even larger diameters are possible.

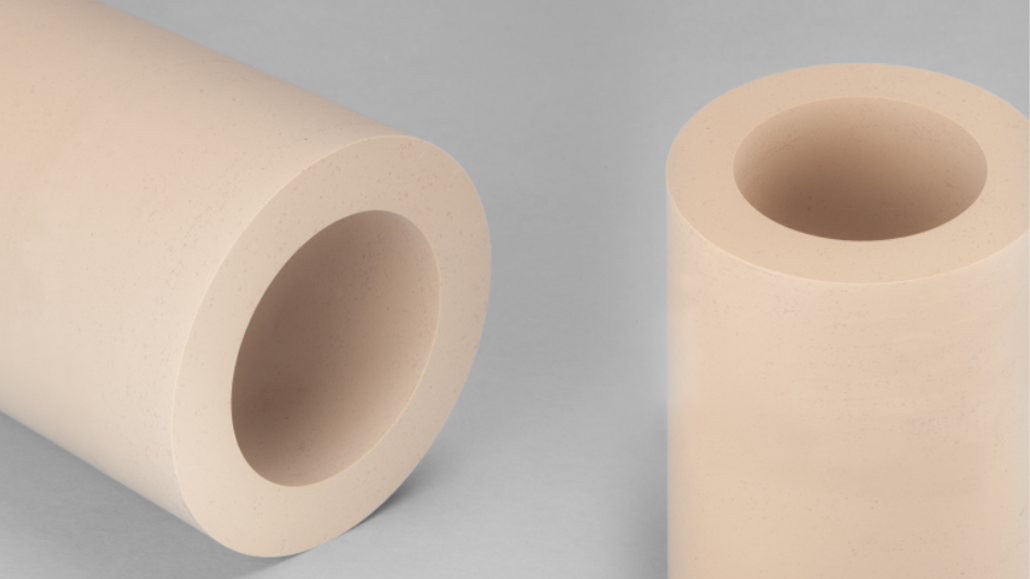

Using quality materials, even for demanding conditions.

We focus on using the highest quality materials, even for the most demanding conditions.

A wide range of materials, including:

- HPU and FDA-certified HPU,

- NBR, EPDM, FPM,

- Pure or "Virgin PTFE", and PTFE with various additives such as bronze, glass fibre, graphite, carbon, Ekonol, PEEK and MoS2,

- FDA-certified rubber materials such as NBR, FPM, EPDM and VMQ,

- materials with a hardness of 73 ShA such as NBR, HNBR, EPDM, FPM.

For demanding operating conditions, we also offer polyurethanes for low temperatures (-67 °C) and PTFE with special additives such as Ekonol®, graphite, carbon, PEEK, etc. We also offer the manufacture of seals in many other materials.

For high quality seals that ensure optimum performance of hydraulic and pneumatic cylinders, contact us. Our expert team will make sure you select the seals that meet your specifications and requirements as quickly as possible.