- All

- Bearing technology

- Linear technology

- Gaskets and seals

- Electric cylinders - actuators

- Industrial wheels & castors

- Standard Elements

- Electric motors

- Gearboxes

- Chains and Sprockets

- Belts

- Pulleys

- Gears and Gear Racks

- Transmission couplings

- Clamping Elements

- Engineering plastics

- Technical rubber

- Hand tools

- Purpose tools

- Workshop equipment

- Measuring tools

- LED work lights

- Pneumatic gauges

- Preparation and regulation of compressed air

- Pneumatic cylinders

- Pneumatic valves

- Accessories

- Cleaning products

- Adhesives

- Adhesive sealants

- Fillers and coatings

- Dosing equipment

- Industrial lubricants

- Vehicles and construction machine lubricants

- Lubricants for garden machinery

- Nautical lubricants

- Metalworking lubricants

- Greases and pastes

- Lubrication equipment

- Oil analysis

- Promotions and discounts

- Machine elements

CategoriesBearing technologyLinear technologyGaskets and sealsElectric cylinders - actuatorsIndustrial wheels & castorsStandard Elements

CategoriesBearing technologyLinear technologyGaskets and sealsElectric cylinders - actuatorsIndustrial wheels & castorsStandard Elements- Show all

- Retaining Rings – Circlips

- Dowel Pins

- Spring Pins

- Rubber Dampers

- Leveling Feet

- Fasteners

- Handwheels, Crank Handles

- Clamping Levers, Tension Levers

- Fixed, Rotating and Folding Handles

- Gripping Handles

- Industrial Hinges

- Control Handles

- Quick Clamps, Power Clamps, Tension Latches

- Indexing Elements

- Latches

- Adjustment Elements, Rotating Knobs, Adjustment Slides

- Magnets

- Rotary Controls

- Other Standard Machine Elements

- Promotions and discounts

Rolling bearings- Show all

- Deep groove ball bearings

- Angular contact ball bearings

- Spindle bearings

- Four-point contact ball bearings

- Self-aligning ball bearings

- Cylindrical roller bearings

- Tapered roller bearings

- Spherical roller bearings

- Needle roller bearings

- Inner rings

- Axial deep groove ball bearings

- Axial cylindrical roller bearings

- Axial needle roller bearings

- Axial spherical roller bearings

- Crossed roller bearings

- Track rollers

- Bearings for screw drives

- Precision bearings for combined loads

- Promotions and discounts

Plain bearingsHousing unitsBearing housingsOther bearingsAccessoriesLinear guidesBall screws - spindlesTrapezoidal screws - spindlesLinear round shaftLinear modulesRadial shaft seals and accessoriesHydraulic sealsPneumatic SealsBraided packingsFlange sealsMechanical sealsV-ring and other axial sealsX-ring sealsDC electric actuatorsAccessories for actuatorsGeneral purpose castorsCastors for rough floorsHeavy duty castorsStainless steel castorsCastors for mobile waste containersTemperature resistance castorsInstitutional castors and wheelsFurniture castors and wheelsRetaining Rings – CirclipsDowel PinsSpring PinsRubber DampersLeveling FeetFastenersHandwheels, Crank HandlesClamping Levers, Tension LeversFixed, Rotating and Folding HandlesGripping HandlesIndustrial HingesControl HandlesQuick Clamps, Power Clamps, Tension LatchesIndexing ElementsAdjustment Elements, Rotating Knobs, Adjustment SlidesRotary ControlsOther Standard Machine Elements - Power transmission

CategoriesElectric motorsGearboxesChains and SprocketsBeltsPulleysGears and Gear RacksTransmission couplingsClamping ElementsSingle phase induction motorsThree phase induction motorsMotor mountingFrequency inverter regulatorsGearbox accessoriesWorm gear boxesPlanetary gearboxesHelical and helical bevel gearboxesVariatorsGeared motorsGall ChainsLeaf ChainsChain LinksChain TensionersChain GuidesChain TightenersTiming beltsPoly V-beltVariator beltsAutomotive beltsAgricultural beltsBelt profiles for drive and transportConnecting plates for timing beltsV-Belt PulleysTiming Belt PulleysTiming Belt BarsFlanges for Timing Belt PulleysRibbed PulleysVariator PulleysGear RacksBevel GearsCylindrical GearsJaw couplingsElastomer couplingsChain couplingsRigid shaft couplingsRubber tyre couplingsGear couplingsCardan couplingsTaper Lock BushingsHubs for TL BushingsScrews for TL BushingsClamping Rings

CategoriesElectric motorsGearboxesChains and SprocketsBeltsPulleysGears and Gear RacksTransmission couplingsClamping ElementsSingle phase induction motorsThree phase induction motorsMotor mountingFrequency inverter regulatorsGearbox accessoriesWorm gear boxesPlanetary gearboxesHelical and helical bevel gearboxesVariatorsGeared motorsGall ChainsLeaf ChainsChain LinksChain TensionersChain GuidesChain TightenersTiming beltsPoly V-beltVariator beltsAutomotive beltsAgricultural beltsBelt profiles for drive and transportConnecting plates for timing beltsV-Belt PulleysTiming Belt PulleysTiming Belt BarsFlanges for Timing Belt PulleysRibbed PulleysVariator PulleysGear RacksBevel GearsCylindrical GearsJaw couplingsElastomer couplingsChain couplingsRigid shaft couplingsRubber tyre couplingsGear couplingsCardan couplingsTaper Lock BushingsHubs for TL BushingsScrews for TL BushingsClamping Rings - Technical plastics and rubber

CategoriesEngineering plasticsTechnical rubberPE plastics (polyethylene)PA plastics (Nylon)POM plasticsPP plasticsPTFE plasticsPET plasticsPEEK plasticsPVDF plasticsPSU plasticsRubber with a smooth surfacePatterned rubber flooringStable rubber flooring

CategoriesEngineering plasticsTechnical rubberPE plastics (polyethylene)PA plastics (Nylon)POM plasticsPP plasticsPTFE plasticsPET plasticsPEEK plasticsPVDF plasticsPSU plasticsRubber with a smooth surfacePatterned rubber flooringStable rubber flooring - Tools

Hand toolsPurpose toolsWorkshop equipmentMeasuring toolsScrewdriversWrenches and RatchetsKnives, blades and sawspoints, chisels and punchesThreading drillsTool setsDrilling machinesHydraulic liftsWheelbarrowsBearing toolsDiagnostics instrumentsTools for seals & gasketsTools for beltsTools for chainsLiner stripsTools for conveyor beltsOther toolsWork glovesWarehouse boxesMarkers and marker coloursZinc spraysAcrylic coloursLeak detectorsTrolleys, cases and tool bagsOther workshop equipmentMeters and gaugesMeasuring slipsOther measuring toolsHand lampsHeadlampsLED floodlightsLED headlights

Hand toolsPurpose toolsWorkshop equipmentMeasuring toolsScrewdriversWrenches and RatchetsKnives, blades and sawspoints, chisels and punchesThreading drillsTool setsDrilling machinesHydraulic liftsWheelbarrowsBearing toolsDiagnostics instrumentsTools for seals & gasketsTools for beltsTools for chainsLiner stripsTools for conveyor beltsOther toolsWork glovesWarehouse boxesMarkers and marker coloursZinc spraysAcrylic coloursLeak detectorsTrolleys, cases and tool bagsOther workshop equipmentMeters and gaugesMeasuring slipsOther measuring toolsHand lampsHeadlampsLED floodlightsLED headlights - Pneumatics

CategoriesPreparation and regulation of compressed airPneumatic cylindersPneumatic valvesAccessoriesPneumatic gaugesAccessories for pneumatic gaugesCompressed air service systemsFilter regulatorsPressure regulatorsFittings and connectorsHose clampsCompressed air gunsNoise dampersVacuum technology

CategoriesPreparation and regulation of compressed airPneumatic cylindersPneumatic valvesAccessoriesPneumatic gaugesAccessories for pneumatic gaugesCompressed air service systemsFilter regulatorsPressure regulatorsFittings and connectorsHose clampsCompressed air gunsNoise dampersVacuum technology - Cleaners and adhesives

Cleaning productsAdhesivesAdhesive sealantsFillers and coatingsDosing equipmentBrake cleanersIndustrial cleaners and degreasersRemoversContact spraysSurface preparation productsAbsorption agentsHand cleanersAutocosmeticsBolt guardsAdhesives for joining cylindrical partsQuick-setting adhesivesUniversal adhesivesAcrylic adhesivesEpoxy adhesivesPolyurethane adhesivesHybrid adhesivesPurpose adhesivesUV adhesivesActivators and primers for adhesivesAdhesive tapesThread sealsSiliconesElastic sealantsLiquid gaskets for flangesLiquid metalsEpoxy coatingsMixing pointsDosing needlesDosing gunsOther dosing equipment

Cleaning productsAdhesivesAdhesive sealantsFillers and coatingsDosing equipmentBrake cleanersIndustrial cleaners and degreasersRemoversContact spraysSurface preparation productsAbsorption agentsHand cleanersAutocosmeticsBolt guardsAdhesives for joining cylindrical partsQuick-setting adhesivesUniversal adhesivesAcrylic adhesivesEpoxy adhesivesPolyurethane adhesivesHybrid adhesivesPurpose adhesivesUV adhesivesActivators and primers for adhesivesAdhesive tapesThread sealsSiliconesElastic sealantsLiquid gaskets for flangesLiquid metalsEpoxy coatingsMixing pointsDosing needlesDosing gunsOther dosing equipment - Lubricants and equipment

CategoriesIndustrial lubricantsVehicles and construction machine lubricantsLubricants for garden machineryNautical lubricantsMetalworking lubricantsGreases and pastesLubrication equipmentOil analysisHydraulic oilsSlideway and sliding oilsIndustrial gear oilsCompressor oilsCirculating oilsHeat transfer oilsChain lubricantsGas engine oilsMultipurpose lubricantsRelease agentsUniversal silicone oilsOther lubricantsEngine oilsGearbox and differential oilsUniversal tractor and construction machine oilsFunctional liquidsOther agents for vehicle maintenanceEngine oils for garden machineryOils for chainsaw chainsMarine engine oilsOther marine lubricantsPenetrating oilsCorrosion protective agentsWelding agentsCutting agentsEmulsions for metalworkingPunching oilsOils for transformationErosion fluidQuenching oilsAdditives for emulsionsGrease equipmentOil equipmentFuel equipmentAdBlue equipmentEquipment for chemicals

CategoriesIndustrial lubricantsVehicles and construction machine lubricantsLubricants for garden machineryNautical lubricantsMetalworking lubricantsGreases and pastesLubrication equipmentOil analysisHydraulic oilsSlideway and sliding oilsIndustrial gear oilsCompressor oilsCirculating oilsHeat transfer oilsChain lubricantsGas engine oilsMultipurpose lubricantsRelease agentsUniversal silicone oilsOther lubricantsEngine oilsGearbox and differential oilsUniversal tractor and construction machine oilsFunctional liquidsOther agents for vehicle maintenanceEngine oils for garden machineryOils for chainsaw chainsMarine engine oilsOther marine lubricantsPenetrating oilsCorrosion protective agentsWelding agentsCutting agentsEmulsions for metalworkingPunching oilsOils for transformationErosion fluidQuenching oilsAdditives for emulsionsGrease equipmentOil equipmentFuel equipmentAdBlue equipmentEquipment for chemicals

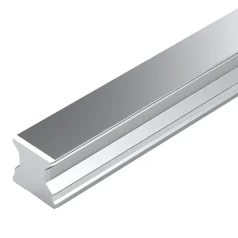

Linear Technology for Precise Mechanical Motion

(8516)Linear engineering solves the problems of precise movements of various machine parts, because the elements are standardised, allow modular construction and greatly simplify design. Using linear engineering elements, we can build quickly and efficiently. When using and installing linear engineering elements, manufacturers' instructions and recommendations must be followed, e.g. special care must be taken when replacing linear carriages. One manufacturer's trolleys cannot be replaced by another manufacturer's trolleys. Each manufacturer uses its own guide profile design. In this case, the guide must be replaced along with the trolley. The preload (clearance) and the accuracy class are also important information. This information is usually not on the bearing itself. Only the machine manufacturer has it and only he can provide a suitable spare part.

Our product range includes linear guides and carriages (round guides, track guides, spindles and nuts, round guides and ball bushings, actuators, linear motors (turntables) and linear modules.

In addition, we also offer customised services such as cutting profiled linear guides, round guides, ball spindles and trapezoidal spindles (cut to length). We can also machine the ends of ball spindles based on your sketches. We also corrosion-protect the guides and carriages.

We have products from various manufacturers such as Hiwin, Ina, Toco and many others.

With years of market presence, expertise and experience, we find the most appropriate and cost-effective technical solution for your application.

Custom-made seals with precision up to 0.1 mm for all industries. High-quality materials, adaptable shapes, and fast execution. Solutions for extreme conditions.